| Category | Assignment | Subject | Engineering |

|---|---|---|---|

| University | University of Surrey | Module Title | ENG2125 – Design Skills |

| Module name | Design Skills |

| Unit of Assessment | FEA Written Assignment |

| Unit of Assessment weighting | 40% |

| Submission date | 13/11/2025 by 16:00 |

| Feedback release date | 04/12/2025 |

Apply the techniques of finite-element analysis using commercial software to the resolution of stress distributions in complex, loaded components.

The task for this assignment is to use finite element simulation to improve the design of a composite panel. It will test your ability to construct a suitable model, analyse the results of the simulation using that model and then improve the structure by changing your design. This process is to be captured by a written report that includes important model parameters, your design and improvement strategy, and results showing a final structure that meets the requirements of the technical brief.

By requesting a report with a fixed word count, you will need to identify and communicate the important aspects of your work clearly and efficiently. You should be talking about the design, structural and simulation parameters, as well as critically analysing the output from simulations.

The aim of this assignment is to decrease the mass and improve the performance of a structural shelf within a series of design constraints. The task requires many modelling techniques used in the preceding weeks of the finite element analysis course. As with many modelling exercises, there are several ways of creating the geometry and structural conditions. It is also not expected that everyone will find the same solution.

The deliverable for the assignment is a report that captures your approach, sound modelling practice, and important simulation output and analysis. You should not submit Ansys files. It is not possible to provide a good report if you have not done the modelling and simulation well.

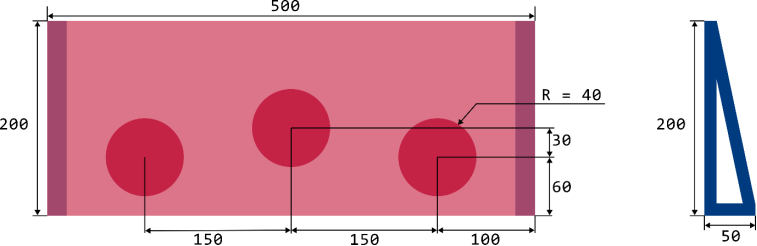

You are tasked with creating a platform assembly that supports a total applied load of 3750 N, which is distributed evenly over three equally sized circular areas (Figures 1 and 2). Loading acts in the vertical direction and must not be redistributed. The length and width of the composite panel are fixed as 500 mm and 200 mm (Figure 2). The platform is made of a composite panel lying in the horizontal plane that is fixed to two metal arms (Figure 1). Each arm has a secure bolted connection to a wall on its vertical edges.

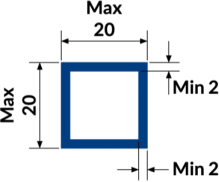

When all the layers of the panel are combined, the total depth of the composite panel should not exceed 20mm. You have flexibility in deciding the cross-section of the arms. When deciding what that cross-section is, you should use engineering principles. However, you must adhere to the constraint that box section members are used, no outer dimension can be more than 20 mm and the wall thickness must not be less than 2mm (Figure 3).

Figure 1. Schematic representation of the platform showing the panel (in red), supporting arms and applied load.

Figure 2. Dimensioned view of the panel (left) showing the three cicular areas where the load is applied, and (right) one of the arms of the platform. Dimensions are in millimetres. The circular areas over which the load is applied (dark red) are of equal radius (40 mm).

Figure 3. The limits in millimetres for the dimensions of the box-section material used in the two arms that support the panel.

The platform assembly should be modelled in a way that is numerically efficient. Approximations used to model constraints, boundary conditions and any contacts should be considered.

The supporting arms should be as light as possible. This goal may be achieved by altering the arms’ cross-section and their material (Section 4). The box sections do not need to be square.

The panel must make best use of the efficiencies offered by a sandwich construction and therefore make good use of a foam core.

The maximum overall displacement under load must nowhere exceed 5 mm. There is no need to consider the factor of safety of the foam core but other components must be demonstrated not to fail. In this context, this requires a factor of safety greater than or equal to one. To limit the scope of the exercise, the factors of safety only need to be considered in tension for any composite materials.

Struggling With Your ENG2125 Assignment? Deadlines Are Near?

Hire Assignment Helper Now!The metal arms are to be made from structural steel or aluminium alloy (using the ANSYS material parameters).

The panel must be of a sandwich construction with a foam core material of Modipur US 569 B produced by HEXCEL (Table 1). This foam core must be applied in 5mm layers.

You may use a mixture of 0o and 90o plies of either Glass Fibre Reinforced Polymer (GFRP) or Carbon Fibre Reinforced Polymer (CFRP) (Table 2). These plies must be applied in 0.5mm layers and show consideration of good engineering practice.

For the foam core, GFRP and CFRP, the material properties that you will need to enter into ‘Engineering Data’ are given in Tables 1 and 2. Parameters required for manual calculation of the factors of safety for GFRP and CFRP layers are given in Table 3. In the panel, you need only consider failure in tension and may ignore compression and shear stresses. Consequently, only tensile strengths for CFRP and GFRP are provided here.

Table 1. Required material properties for the isotropic material Modipur US 569 B – taken from [http://pdf.directindustry.com/pdf/hexcel-corporation/modipur-us-569-b/37685-676334.html]

|

Tensile Modulus |

94 MPa |

|

(Tensile Strength) |

(1.26 MPa) |

|

Poisson’s Ratio |

0.35 |

|

Nominal Density |

150 kg/m3 |

Table 2. Required properties for the orthotropic CFRP and GFRP materials – adapted from [http://www.performance-composites.com/carbonfibre/mechanicalproperties_2.asp]

|

|

CFRP |

GFRP |

|

Young’s Modulus (X) |

135 GPa |

40 GPa |

|

Young’s Modulus (Y) |

10 GPa |

8 GPa |

|

Young’s Modulus (Z) |

10 GPa |

8 GPa |

|

Poisson’s Ratio (XY) |

0.3 |

0.25 |

|

Poisson’s Ratio (YZ) |

0.3 |

0.25 |

|

Poisson’s Ratio (ZX) |

0.3 |

0.25 |

|

Shear Modulus (XY) |

5 GPa |

4 GPa |

|

Shear Modulus (YZ) |

5 GPa |

4 GPa |

|

Shear Modulus (ZX) |

5 GPa |

4 GPa |

|

Density |

1600 kg/m3 |

1900 kg/m3 |

Table 3. Ultimate strengths required for calculating the factors of safety of the panel layers – adapted from [http://www.performance-composites.com/carbonfibre/mechanicalproperties_2.asp]

|

|

CFRP |

GFRP |

|

Ultimate Tensile Strength (X) |

1.5 GPa |

1 GPa |

|

Ultimate Tensile Strength (Y) |

0.05 GPa |

0.03 GPa |

|

Ultimate Tensile Strength (Z) |

0.05 GPa |

0.03 GPa |

Your written report must be between 800 to 1300 words and include a word count. The word count does not include equations, figure and table captions and table content. Do not use appendices and include no more than ten figures.

There are many instructions relating to the report. It is suggested that you make sure that you have a suitable working simulation before focussing on those instructions. Those instructions are summarised here (in Section 5).

Your report should begin with a brief introduction that summarises the aim of the work and the important features of your initial model.

The methods that you have used to iterate to an improved design should be presented briefly and concisely. This should include the types of output data considered, how the output was used to make design decisions, what those decisions were, and the mechanical engineering principles used to inform the decisions.

You should demonstrate that your FE results are accurate and verify that the model is sound.

Your results, discussion and conclusion should draw on the technical issues identified in the tutorial exercises and questions that have been covered during the course.

Most of the report should focus on the final design and its structural performance. Results should be presented and your discussion should analyse those results.

The mass and factors of safety of the panel and frames should be tabulated. Contour plots of the displacement of the whole structure, stress in the frame, and 0o and 90o stresses in the most critical plies should be presented and discussed. This discussion should substantiate the factors of safety.

At the end of the report, you should have a conclusion and include some brief comments on the limitations of this work and any recommendations you may have to further improve the model and simulation.

Do not present the report as a guide on how to use Ansys software. Instead, you should include the structural, modelling and simulation information that would allow somebody to recreate the simulation in another finite element analysis software package. Do not include an abstract.

The assignment should be submitted as a single .pdf document via SurreyLearn. It will be subject to a Turnitin check.

The rubric used for feedback can be found at the end of this document. This gives further details of the criteria against which you will be assessed.

Feedback will be provided through the rubric, written comments and a video covering more general trends for the whole cohort.

Opportunities for formative feedback on the modelling and simulation will be available during the timetabled tutorial sessions in weeks 6 and

|

Presentation (30%) |

90-100% Exceptional |

80-89% Outstanding |

70-79% Excellent |

60-69% Very good |

50-59% Good |

40-49% Adequate |

0-39% From missing to below expectations |

|

Structure and Overall Presentation (10%) |

- Exceptionally structured report, with exceptional appearance, layout and flow of information. - The report’s structure and presentation would be considered exceptional in a professional context. |

- Outstandingly structured report, with outstanding overall appearance, layout and flow of information. - The report exceeds professional norms. |

- Excellent structure to the report. - Overall appearance, layout and flow of information is also excellent. - Titles and labelling heighten the reader’s sense of structure. |

- Very good structure to the report. - Overall appearance, layout and flow of information is also very good. - Titles and labelling contribute well to the reader’s sense of structure. |

- Good structure to the report. Overall appearance, layout and flow of report is also of a good standard. Information is presented in a sensible order. |

- Structure of the report is somewhat organised. Layout and flow of information is understandable but not intuitive. |

- Disorganised presentation of information. - Layout is untidy and there is no clear flow or progression of information. |

|

English Usage (10%) |

- Exceptional use of technical English, including spelling and grammar. - Exceptional clarity and accuracy, and error-free. - Faultless applications of acronyms. |

- Outstanding use of technical English, including spelling and grammar. - Demonstrating precision and efficiency throughout. - Faultless applications of acronyms. |

- Excellent use of technical English, including spelling and grammar. - Rigorous use of acronyms and passive voice. - Excellent clarity and precission. |

- Very good use of technical English, including spelling and grammar. - Only occasional slips in use of e.g., acronyms and passive voice. |

- Good use of technical English, including spelling and grammar. - Some minor slips present in use of, for example, acronyms and passive voice. |

- Adequate use of technical English, including spelling and grammar. - Many technical errors in writing but comprehension is largely unaffected. - Passive voice not used throughout. |

- Below expectations for spelling and grammar. - Difficult to follow. - Includes, for example, many mistakes and poor use of acronyms, tense and passive voice. |

|

Format of Figures, Tables and Captions (10%) |

- All formatting conventions are applied with no errors. - Figures, tables and equations have exceptional clarity and consistency. - All figures, tables and equations are cited correctly and in sequence in the text. - Captions add great value and are efficiently written. |

- All formatting conventions are applied with no errors. - Figures tables and equations have outstanding clarity and consistency. - All figures, tables and equations are cited correctly and in sequence in the text. - Captions add value and are efficiently written. |

- All formatting conventions are applied with only occasional slip. - Figures have excellent clarity and consistency. - All figures, tables and equations are cited correctly and in sequence in the text. - Captions are concise, clear and appropriately located. |

- All formatting conventions are applied well with few errors. - Figures have very good clarity and consistency. - All figures, tables and equations are cited correctly and in sequence in the text. - Captions are appropriately located. Units are used correctly. |

- Most formatting conventions are applied with some errors. - Figures and tables are mostly cited correctly. - Units and data are presented with few errors in, e.g., significant figures. - Some views have not been selected carefully to illustrate the output. |

- Some formatting conventions are applied well but with errors. - Content of figures is clear but views may not be chosen to best effect. - Data is provided but not always legible or consistent in format. - Citations are not always used correctly the majority of figures, tables and equations are not presented in sequence. - Artefacts from screen shots may not have been removed |

- Below expectations for formatting and use of figures, tables and captions. - Data is unclear and units are missing or inconsistent. - Citations in text are not used appropriately. - Artefacts from screen shots may not have been removed. - More than the ten allocated figures have been used. |

Order Custom Answers for ENG2125 Assignment

Order Non Plagiarized AssignmentNeed help with your ENG2125 Design Skills FEA Written Assignment ? You are at the right place. Our platform provides the best assignment help in UK. We have talented writers who can provide assignments without any plagiarism and 100% original content. You are assured that our Engineering Assignment Help will make you productive and help you achieve high grades in your academic year. No doubt about it! We also provide free sample assignments for your guidance. Contact us now!

Hire Assignment Helper Today!

Let's Book Your Work with Our Expert and Get High-Quality Content