| Category | Assignment | Subject | Management |

|---|---|---|---|

| University | Temasek Polytechnic | Module Title | EBM3005 Energy Management and Audit |

| Word Count | 500 Words |

|---|---|

| Assessment Type | Report |

The air-conditioning system uses the most energy in a typical air-conditioned building in Singapore and may account for as high as 60% of the overall electricity consumption of a building. It is therefore imperative that, in evaluating the energy performance of a building, there will be greater emphasis on the energy usage and performance of the building’s air conditioning system.

The project hence focuses on evaluating the energy performance of a water-cooled central chilled water plant (CCWP) and air distribution system (ADS) of a centralised air conditioning system. Two methodologies of data collection (audit) and evaluation have been applied.

Objective: Energy performance analysis of a water-cooled CCWP

| Deliverable | Task Description | Weightage | Submission Date |

|---|---|---|---|

| Report 1 | Live Energy Audit | 20% total (Individual: 16%, Group: 4%) | 9 June 2025 |

| Report 2 | Operating Data from BMS | 25% total (Individual: 16%, Group: 9%) | 18 August 2025 |

| Reflective Journal | Learning Process | 5% (Individual only) | 18 August 2025 |

Deliverables: 500-word Word document

| # | Items | Remarks | Marks (10) |

|---|---|---|---|

| 1 | Effectiveness of F2F lessons, tutorials, video recordings, SW26B chiller plant tour & IBEC airside systems’ (IAQ audit) practical sessions | Nil | 5 marks |

| 2 | Process of applying learning from Topics 1 and 2 to the project scenario | Nil | 5 marks |

Objective: Energy performance analysis for a water-cooled CCWP

Data collection: Live Energy Audit

| # | Items | Remarks | Marks |

|---|---|---|---|

| 1 | Data collection – Table 1 to Table 10, including photo-evidence (if available) | Annexe A: Live-audit data | 20 |

| 2 | Calculation of CHW & CW flow rates for CCWP and CHW flow rates for the AHUs | Annexe B: Schedule of CCWP Equipment | 16 |

| 3 | Sketching of system curves on pump curves: CHW loop & CW loop: – Design flow vs. Design head → Design Point (DP) – Measured Flow vs. Measured Head → Operating Points (OP1: WPL formula, OP2: VFD formula, OP3: Flow-meter reading) | Annexe C: Specifications for pumps & cooling towers | 8 |

| 4 | Analysis of plotted system curves – Design vs. Actual system curve | Based on Item 3, Table 2, Table 4 & Table 10 data | 3 |

| 5 | Evaluation of space conditions (Table 7) with SS 554:2016 for non-compliance | TP Library link to SS554:2016 | 3 |

| 6 | Calculate various performance parameters of the water-cooled CCWP and ADS | Performance parameters under Individual Scope of Work & Annexe D: Summary table with hints for calculation | 50 |

| 7 | Comparison and analysis of air-distribution system efficiency with Green Mark ENRB 2017 criteria | Annexe E: Hints for comparison Annexe F: Schematic of BMS for AHUs in IBEC | 25 |

| 8 | Assessment of chiller efficiency under actual operating conditions vs rating conditions | Refer to the screenshot below for PL data of the ETI-50 chiller |

4. For the CHW circuit, please refer to the following:

a. The actual system curves which you have sketched in item 3 above.

b. The evaporator (chilled) water flow rates are summarised in Table 10 of the

template.

Based on these sources of information, discuss possible reasons why the actual system curves lie above or below the design system curve.

[Please DO NOT treat (a) and (b) as separate questions to be answered!]

5. Evaluate whether the measured space conditions in Table 7 comply with the requirements of SS 554: 2016. (Note: for the IBEC renovation works, design & construction started in late 2019 and were completed by late 2020 / early 2021).

6. Calculation of performance parameters of the water-cooled CCWP and ADS:

a. Power factor of the chiller compressor

b. Motor Input Power (kW) of the CHWP

c. Motor Input Power (kW) of the CWP

d. Motor Input Power (kW) of the CT

e. Total Input Power (kW) of the CCWP

f. Actual Cooling Capacity (RT) of the Chiller

g. Part load (%) of the Chiller

h. Efficiency (kW/RT) of the Chiller

i. Efficiency (kW/RT) of the CHWP

j. Efficiency (kW/RT) of the CWP

k. Efficiency (kW/RT) of the CT

l. System Heat Balance (%), of the CCWP (based on Primary & Secondary Loop)

m. Operating System Efficiency, OSE (kW/RT), of the CCWP

n. Cooling capacity (RT) of AHU 1-1 and AHU 1-2

o. Motor Input Power (kW) of AHU 1-1 and AHU 1-2

p. Efficiency (kW/RT) of AHU 1-1 and AHU 1-2

q. Room Sensible Heat Gain (RSHG) of the spaces served by AHU 1-1 & AHU 1-2

7. In the Green Mark (GM) for Existing Non-Residential Buildings (ENRB) 2017 criteria, air distribution systems need to achieve 0.28 kW/RT efficiency or better. With reference to the efficiency of both AHUs (calculated based on CHW flow rate from USFM and electrical data from DPM), analyse the possible reason(s) for the difference between the actual efficiencies as compared to the baseline value above prescribed in GM ENRB 2017.

[Hint: Refer to the AHU data from the BMS (viz. Table 6), and consider also the

factors listed in (a) through (e) below, in your answer:

a) Chilled water cooling coils’ control valve positions

b) Cooling coils’ actual CHW flow rate and design CHW flow rate

c) Actual SA temperature, actual RA temperature and set-point RA temperature

d) Relationship between RSHG, SA flow rate, SA temperature and RA temperature

Vsa(m3/s) = RSHG (kW)/1.206 × (TDB1 – TDB4)°C

e) SA fan speed and its relationship to SA flow rate and fan motor input power. You will also need to refer to Annexe E for other relevant material.

8. Complete the table below:

| Parameter | Based on Rating Conditions (corresponding to actual operating PL) | Based on Actual Operating Conditions (based on FM & DPM readings) |

|---|---|---|

| Entering Chilled Water Temperature (ECHWT) | ||

| Leaving Chilled Water Temperature (LCHWT) | ||

| Entering Condenser Water Temperature (ECWT) | ||

| Leaving Condenser Water Temperature (LCWT) | ||

| PL for Chiller (%) | ||

| EE for Chiller (kW/RT) | ||

| HB for Chiller (%) |

Submit Your EBM3005 Assignment Questions & Get Plagiarism-Free Answers

Order Non-Plagiarised Assignmenta. Based on your summary in the above table, assess the impact of the actual operating conditions on the chiller’s energy efficiency (or Coefficient of Performance, COP), relative to the rating conditions. (Hint: refer to what you

have learnt in ACMV Topic 3 – Chilled Water Systems and explain via a sketch of the vapour compression refrigeration cycle.

b. Explain whether the computed energy efficiency of the chiller is within an acceptable level of accuracy.

Technical specification of cooling Coil for AHU 1-1 & AHU 1-2 – with the design/rated CHW flowrates and corresponding water pressure losses indicated

CHWP and CWP system curves – with the Design Points and Operating Points indicated

(c) Insert the group’s completed work for items 6 through 8 immediately after items (a)(i) and (a)(ii) above.

The sequence will thus be as shown below:

Cover page for Individual Work

Table 1 thru Table 10 (Individual Work)

Completed Work for Item 2 thru Item 5 (Individual Work)

Cover page for Group Work

Completed Work for Items 6 (Individual Work) thru’ Item 8 (Group Work)

Each group is to have a maximum of 4 students.

Objective: Energy performance analysis for a water-cooled CCWP

Data collection: Operating data from BMS (refer folder under the project brief)

CCWP Schematic: Annexe G

| # | Items | Remarks | Marks |

|---|---|---|---|

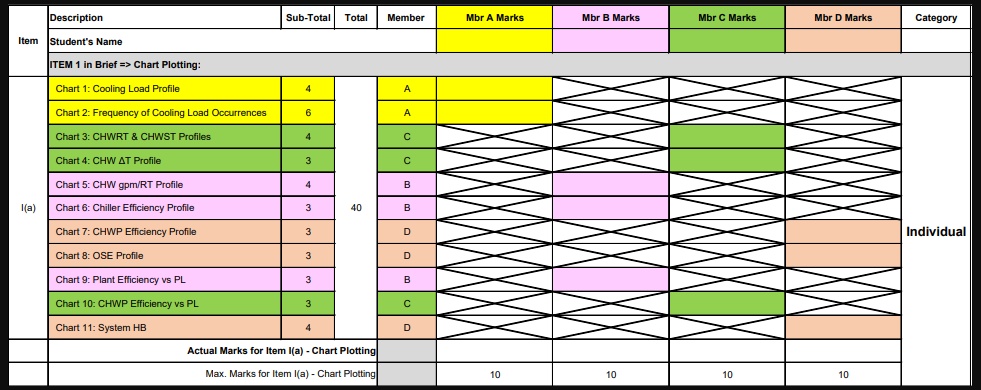

| INDIVIDUAL | |||

| 1 | Chart Plotting: System parameters | List of charts & calculations under Individual Scope of Work | 40 marks |

| 2 | Calculations: Daily average parameters | 24 marks | |

| GROUP | |||

| 3 | Summary tables and plant operation checklist (based on the charts) with calculations (Tables H1 – H3) | Annex H: Summary Tables | 14 marks |

| 4 | Comment on the following:

|

Refer to: – Table H1 & H2 with Chart 9 & 10 – Chart 1 – Topic 2, Sect 2-5, slide 18 (minimum OSE) |

7 marks |

| 5 | Select and EXPLAIN the minimum number of instruments/sensors to be installed in the chiller plant for determining OSE and HB of plant and individual chillers. | Annex G: Plant schematic | 5 marks |

| 6 | Select an alternative chiller to replace the existing 1200 RT constant speed centrifugal chiller operating on weekends.

Give reasons. Include a simple payback (SPB) analysis. |

Annex I: Assumptions for alternative chiller | 10 marks |

4. (a) Comment on the trend of Operating System Efficiency vs PL (Chart 9) and CHWP Efficiency vs PL (Chart 10).

(Hint #1: By means of a heavy broken red line, mark in the Daily Average overall chiller plant efficiency (from Table H1) and the Time-Weighted Average chiller plant efficiency (from Table H2), onto Chart 9, to help clarify your explanation).

(Hint #2: in the same way as you calculated the TWA overall chiller plant efficiency – ie. OSE – using Excel, similarly compute the TWA efficiency of the CHWP.

(Hint #3: By means of a heavy broken red line, mark in the Daily Average CHWP efficiency (from Table H1) and the Time-Weighted Average CHWP efficiency, onto Chart 10, to help clarify your explanation).

(b) Compare the Daily Average plant efficiency and TWA plant efficiency against the minimum OSE specified in the GM ENRB 2017 criteria, and hence explain which level of Green Mark award the building is most likely to qualify for.

(Hint #3: refer to your Chart 1 to determine the peak cooling load of the building and then to Topic 2, Section 2-5 notes, slide 18 for the minimum OSE required).

(c) With reference to Table H2:

i. Interpret the significance of the value for ‘% Heat Balance within ±5% error…’ in the last row of Table H2.

ii. Examine any three (3) possible reason(s) for the Heat Balance deviating from the prescribed ±5% limits. (Hint: mark in a heavy broken red line onto the plotted HB profile (Chart 11) to show the ±5% band, to help clarify your answer.)

5. Propose and explain the minimum number of each type of instrument/sensor to be installed in a chiller plant, for determining the OSE and system HB. Also, propose and explain the modifications required in terms of the required quantity of the relevant instruments/sensors if each chiller’s efficiency and Heat Balance are to be determined as well.

6. (a) From the raw data provided for Sunday, and using Excel:

i. Plot the Plant Cooling Load vs Time profile, using the same y-axis (RT) and x-axis (time) scale as for Chart 1. [Hint: scale the x-axis using 30-min intervals]. What do you observe about the general trend in the cooling load for Sunday as compared to that of weekdays?

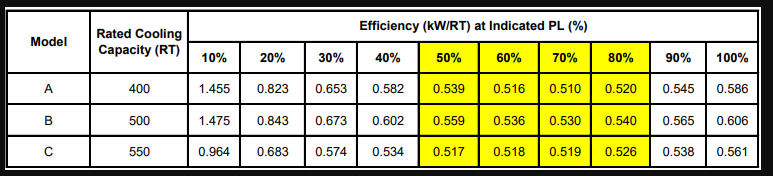

ii. With reference to the procedure outlined in Annexe I, select a suitable, alternative model of chiller to serve the existing cooling load profile, by referring to the table below:

Part-Load Performance for Alternative Models of Chiller To Meet Sunday’s Cooling Load

(b) The existing chiller serving the Sunday cooling load was originally a constant speed centrifugal chiller of 1200 RT rated capacity. Evaluate the cost-benefit of replacing this centrifugal chiller with the selected alternative model by using the Simple Payback method. Refer to Annex I for the relevant assumptions.

Each student is required to write a maximum 500-word Reflective Journal (Arial, 12-point font size), describing your learning experience while doing this Project. In particular:

i. Explain whether and how the F2F lessons, tutorials, video recordings, and the IBEC CCWP & airside systems’ tour, have helped you in doing the Project.

ii. Highlight whether and how the topics you have learnt in EMAUDIT Topic (ACMV System Architecture) and Topic 2 (Measurement & Verification) may have helped you to better understand the application of the concepts covered in the Project.

| Item | Description | Max. Mark | Member | Total Mark |

|---|---|---|---|---|

| a | Power Factor of the Chiller | 5 | A | 50 |

| e | Total Chilled Water Plant Input Power | 10 | ||

| f | Actual Cooling Capacity of the Chiller | 16 | ||

| g | Part Load of the Chiller | 10 | ||

| h | Chiller Efficiency | 9 | ||

| b | MIP of CHWP | 20 | B | 50 |

| d | MIP of CT | 13 | ||

| i | CHWP Efficiency | 10 | ||

| k | CT Efficiency | 7 | ||

| c | MIP of CWP | 20 | C | 50 |

| j | CWP Efficiency | 10 | ||

| l | System HB (based on primary & secondary CHW loop) | 10 | ||

| m | Chiller Plant OSE | 10 | ||

| n | Cooling Capacity of AHU-1/1 and AHU-1/2 | 21 | D | 50 |

| o | MIP of AHU-1/1 and AHU-1/2 | 10 | ||

| p | Efficiency of the AHUs | 7 | ||

| q | RSHG of Spaces Served | 12 | ||

| Discussion Questions (GROUP Work) – Q7 | 10 | Group | 25 | |

| Discussion Questions (GROUP Work) – Q8 | 15 | |||

Take our academic assistance & Get 100% plagiarism-free papers

Buy Today Contact UsStruggling with your EBM3005 Energy Management and Audit? Well! Don't Worry. You are at the right place. Our platform provides assignment help in Singapore. We have experienced writers who provide high-quality, no-plagiarism assignments with 100% original content, and we are assured that our Management Assignment Help will make you productive and help you achieve high grades in your academic year. And we also provide free assignment samples that have been written by the phd expert writers. Contact us now!

Hire Assignment Helper Today!

Let's Book Your Work with Our Expert and Get High-Quality Content