| Category | Assignment | Subject | Management |

|---|---|---|---|

| University | NATIONAL ECONOMICS UNIVERSITY | Module Title | L/618/5036 - Unit 4: Leadership and Management |

| Unit Code, Number and Title: | L/618/5036 - Unit 4: Leadership and Management | Academic year: | 2024-2025 |

| Semester: | 2 | Assignment Title: | LM A2.1: Presenting Motivational Strategy |

| Assignment no.: | (Assessment 2 of 2, Individual assignment) | Assessment: | ECONOMICSBTEC HIGHER NATIONAL DIPLOMA IN BUSINESS (RQF) |

LO3: Develop a motivational strategy to optimise organisational performance.

LO4: Apply leadership and management approaches to managing performance to ensure continuous improvement.

The Piaggio Group is the largest European manufacturer of two-wheel motor vehicles and one of the world leaders in its sector. The Group is also a major international player on the commercial vehicle market 1.

Established in 1884 by Rinaldo Piaggio, since 2003 the Piaggio Group has been controlled by ImmsiS.p.A., an industrial holding listed on the Italian stock exchange. Roberto Colaninno is the Chairman and Chief Executive Officer of the Piaggio Group, Matteo Colaninno is Deputy Chairman. The Piaggio Group has been listed on the Italian stock exchange since 2006. The Piaggio Group product range includes scooters, motorcycles and mopeds from 50 to 1,400 ccmarketed under the Piagio, Vespa, Gilera, Aprilia, Moto Guzzi, Derbi and Scarabeo brands. The Group also operates in the three- and four-wheel light transport sector with its Ape, Porter andQuargo (Ape Truck) ranges of commercial vehicles. The Piaggio Group brand portfolio contains someof the most distinguished and historic names in the two-wheeler industry, from Gilera (founded in1909) and Moto Guzzi (founded in 1921) to Aprilia (which in just over twenty years has establisheditself as the most successful Italian and European vehicle manufacturer in the world motorcyclingchampionships) and Vespa, the extraordinary two-wheeler that has come to be regarded as “the”scooter: with more than 18 million vehicles produced since it made its debut in 1946, the Vespa is anincredibly long-lived market success as well as one of the best known icons of Italian style andtechnology in the world.

The Piaggio Group is headquartered in Pontedera (Pisa,Italy) and has production plants in: Pontedera (Pisa),which produces Piaggio, Vespa and Gilera branded two-wheelers, light transport vehicles for the European market and engines for scooters and motorcycles; Noale (Venice), a technical centre for the development of motorcycles and the base of Aprilia Racing; Scorzè (Venice), which produces Aprilia and Scarabeo branded two-wheel vehicles; Mandellodel Lario (Lecco, Italy), which produces Moto Guzzi vehicles and engines; Baramati (in the Indian state of Maharashtra), which produces three- and four-wheellight transport vehicles for the Indian market, diesel and turbodiesel engines for the Group’s commercial vehicles,and, since the beginning of 2012, the Vespa scooter forsale on the Indian market; China with a joint venture ( Zongshen Piaggio Foshan Motorcycles, based in Foshan in the province of Guangdong); VinhPhuc (Vietnam) which produces Vespa and Piaggio scooters for the local market and the ASEAN area.

Buy Answer of This Assignment & Raise Your Grades

Request To By AnswerThe opening of Piaggio Vietnam factory on the 24th June 2009 has marked a milestone to thedevelopment of Piaggio in Vietnamese market. With the investment of 30 million USD, the factory isexpected to produce more than 100,000 units a year when reaching the maximum operational capacity.The Piaggio Vietnam Co.Ltd is one of the most important steps in the strategic development forglobally manufacturing operations of the Piaggio Group.In October 2010, the 50,000th Vespa was shipped as a milestone marking the development of PiaggioVietnam Co.Ltd after 15 months of operations. Concerning engine assembly and testing, in Italy, in December 2011, a new assembly line for LEmengines was developed and testing completed at the supplier's premises. The line was dispatchedto Vietnam in the first few weeks of January 2012 and installed in the new engine assembly building inFebruary. A procedure was established to issue orders for aluminum processing lines (production start-up in the second half of 2012) and cylinder head processing lines (production start-up in the first half of 2013).

Work began to install a third vehicle assembly line, and production start-up was scheduled for the firstfew months of 2012. In Mar 2012, the opening of the Engine Plant helped the Piaggio Vietnam toincrease the production capacity from 140,000 units per year to 300,000 units per year. Expansion of the industrial site in Vietnam was completed, with new industrial buildings built formechanical processing and for engine and spare parts assembly. Work also began to transfer the vehiclewelding department from the assembly plant to a more suitable area inside the new spare parts warehouse.

The Industrial complex of Piaggio Vietnam in Vinh Phuc, including the Research and ProductDevelopment Center for two-wheelers, the Engine plant, the Assembling plant, cooperates closely withthe Group to develop motor vehicles and serves markets in Asia – Pacific.

In 2023, Piaggio Vietnam merged two projects to develop a world-class Two-wheeler assembly plantand Engine plant, increasing the total investment capital from 90 million USD to 165 million USD;increasing the production scale from 250,000 vehicles/year to 400,000 vehicles/year for domesticdistribution and export, the engine production and assembly scale from 300,000 engines to 400,000engines/year, making Piaggio Vietnam one of the Group's most important factories globally.

Piaggio Vietnam Co., Ltd. has continuously developed, affirmed its brand and position in the top 200largest enterprises in Vietnam in 2024, top 50 FDI enterprises with impressive business results,received the Golden Dragon Award 3 years 2021, 2022, 2024 and ranked as one of the best place towork in Asia.

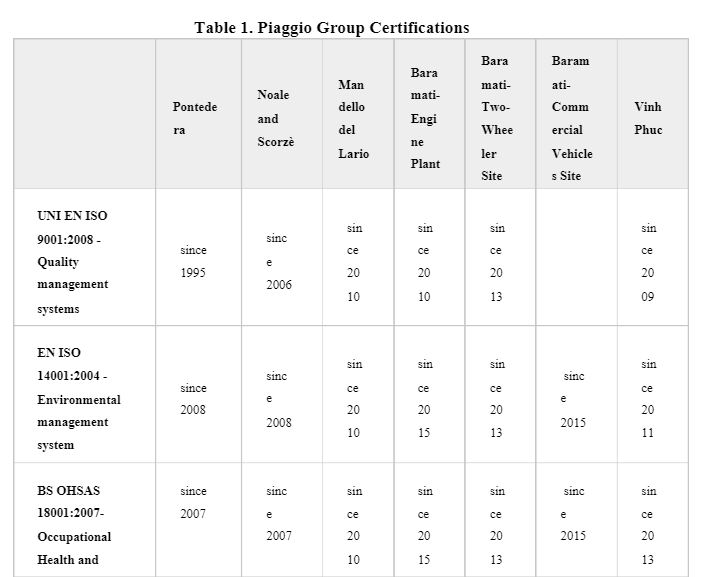

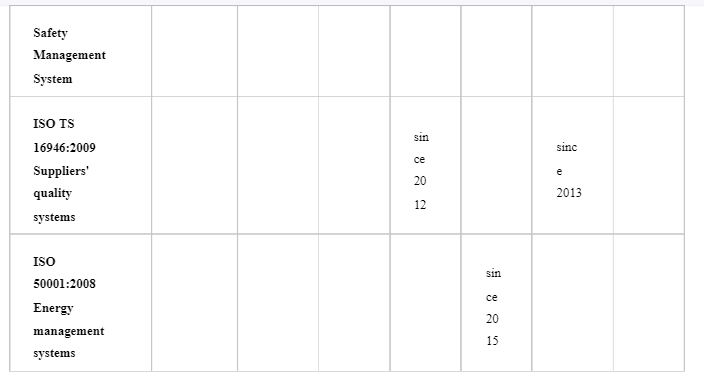

Piaggio’s production sites in Italy – Noalè-Scorze and Mandello del Lario – as well as in Vietnam and the Indian production site 2W have for many years held certifications for Quality (ISO9001), Environment (ISO 14001) and Occupational Health and Safety (BS OHSAS 18001).Quality, Health and Safety, Employee Benefit and Well being, Environmental policies established by Top Management and are proof of the reliability of Management Systems which are applied with the contribution of managers from all functions and the individuals who work in them.Safeguarding and improving the health and safety of workers is integral to the Piaggio Group'soperations and strategic within the framework of its more general objectives. This principle is valid and a dopted in all countries where the Piaggio Group operates. In particular, the Group has taken concrete actions for:

Health protection for workers in such a complex industrial context as the Piaggio Group, both in Italyand abroad, can only take place through an adequately structured organisation which specifically aimsto foster as far as possible a safety "culture" within the Company. Therefore, the belief that safety must focus on conduct and daily operations is disseminated at all levels; this approach has led the PiaggioGroup to adopt safety management standards that are very similar in all countries where it operates,regardless of whether legal constraints are not as strict as company standards.

Achieve Higher Grades This Assignment Solutions

Order Non Plagiarized AssignmentThe Piaggio Group therefore guarantees its employees a pleasant working environment and safe working conditions,beyond the minimum conditions established by law. In this framework, sites in Italy and Vietnam andthe Vespa plant in India have an Occupational Health and Safety Management System certified toOHSAS 18001 by an accredited certification body.The Health and Safety Management System implemented at Piaggio includes a large body of documents that, starting from the Safety Manual which outlines the policies issued by Management, are implemented in the Management Procedures (covering the entire company organisation), in the Operating Procedures (which regard only some company structures) and in Work Instructions that illustrate how every single operation is to be carried out correctly.

In line with Health and Safety Management System requirements, the Piaggio Group has identified safety training as the key driver for disseminating a culture and fostering a conduct focused on safety leadership and for generating commitment and steering conduct.Promoting health is another important aspect for the Piaggio Group, and this is achieved based on twoareas of action: free testing and information campaigns on healthy lifestyles. Each Group site has a health unit for prevention, surveillance and first aid, manned by specialist medical and paramedical staff.

At Piaggio Vietnam, the health and safety of employees and everyone working within the Company system are considered as being of the utmost importance, confirming the key principle that promoting and maintaining health and safety in the workplace is one of the primary responsibilities of managers.To this end, managers at all levels are required to develop, implement and monitor the Health and Safety Management System defined by the Occupational Safety and Medicine unit of Piaggio Vietnam,in conjunction with its partners.The main priority of the Company, in terms of it being an organised system, in compliance with local laws, international health and safety standards and Piaggio Group policies. In this framework, it guarantees that objectives to improve occupational health and safety are pursued through an Occupational Safety and Medicine unit.

The presence of a doctor and professional nurses at Occupational Safety and Medicine unit means that medical assistance can be provided at the site in the case of minor illnesses, to carry out medical tests and administer medicines that are reimbursed by the Vietnamese state, thanks to an agreement with the local welfare department. The Medical Centre also organised a "Nutrition Day" in June dedicated to the health of employees' children, which is reported inthe section on Industrial Relations. All employees had annual health checks in December, as of regulations. Employees who work in conditions of discomfort, such as painting and welding, have 2 occupational disease check ups, in June and December.

Along with personnel training, actions also focused on consolidating a culture of safety, including:

You are a professional consultant invited by CEO of Piaggio Vietnam . You are required to prepare areport, citing relevant research, which addresses the following tasks in the areas outlined below:

Develop a motivational strategy to optimise organisational performance

Apply leadership and management approaches to managing performance to ensure continuous improvement.

Get the Solution of This Assignment. Hire Experts to solve this assignment Before your Deadline

Order Non Plagiarized AssignmentAre you having trouble understanding L/618/5036 - Unit 4: Leadership and Management Assignment? Don't worry! We bring you the best online assignment help service. With our management assignment help service, you will get original content that is AI-free and human-written. We complete your assignment before the deadline so that you can submit it without any stress. We also offer free assignment samples that will help you clear your concepts. Now stop stressing and get expert help! Order Now!

Hire Assignment Helper Today!

Let's Book Your Work with Our Expert and Get High-Quality Content